Custom safety valve design solutions are vital in industries where protecting equipment and personnel is non-negotiable. Tailored to meet specific application needs, these valves exceed standard performance benchmarks. With expert guidance, businesses can confidently address safety valve specifications, regulatory compliance, and rigorous testing procedures.

Each industrial environment presents unique challenges. Professionals in safety valve engineering help navigate these complexities, ensuring that every custom valve solution aligns with both safety regulations and operational performance goals. This collaborative approach empowers companies to implement reliable and effective safety strategies.

What Are Custom Safety Valve Design Specifications and Why Do They Matter?

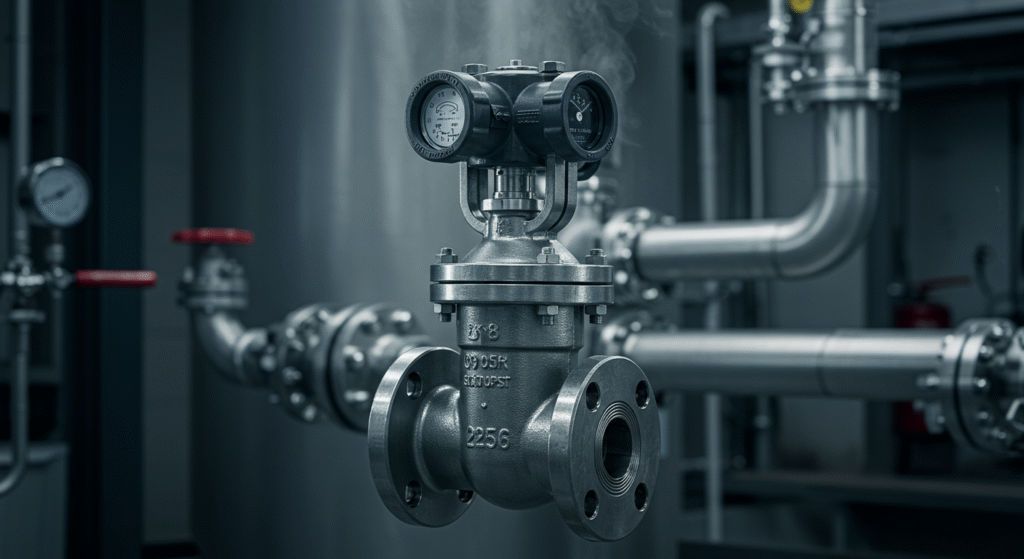

Custom safety valve design specifications are the detailed performance criteria established during the valve development process. Unlike off-the-shelf options, custom valves are engineered with specific considerations like fluid properties, pressure thresholds, and environmental conditions.

These specifications are critical because safety valves are often the last line of defense against catastrophic overpressure scenarios. A well-designed valve minimizes risks such as leaks, system failures, and explosions. Additionally, custom designs enhance valve reliability, extend service life, and reduce operational disruptions—ensuring both safety and cost-efficiency.

Which Key Parameters Define Safety Valve Design Specifications?

Designing a custom safety valve requires careful attention to several parameters:

- Set Pressure: The point at which the valve opens to relieve system pressure.

- Flow Capacity: Sizing must accommodate peak flow conditions to avoid bottlenecks.

- Material Selection: Materials must be compatible with media and resistant to corrosion or chemical degradation.

- Seal Design: Durable sealing elements prevent leaks and ensure consistent functionality.

- Regulatory Compliance: Adherence to codes like ASME, ISO, or API ensures safety and legal conformity.

Each of these factors must be accurately defined to deliver effective and compliant safety valve solutions.

How Do Material Choices Impact Custom Safety Valve Performance?

Material selection directly impacts the functionality and longevity of custom safety valves. Metals like stainless steel, Hastelloy, and Monel offer corrosion resistance and strength, making them suitable for high-pressure, high-temperature, or chemically aggressive environments. Elastomers and polymers may be used in seals for flexibility and chemical resistance.

Choosing the right material ensures compatibility with the fluid media and operating conditions, reducing wear and enhancing reliability. Mechanical properties like tensile strength, fatigue resistance, and thermal conductivity also influence a valve’s performance under dynamic conditions. Thoughtful material selection enhances both immediate functionality and long-term durability.

What Role Does Fluid Dynamics Play in Safety Valve Design?

Fluid dynamics is fundamental in custom safety valve design. It examines how gases or liquids behave when the valve is activated, influencing flow paths, pressure drop, and valve responsiveness.

Designers use computational fluid dynamics (CFD) to simulate and refine valve behavior under different flow conditions. This ensures the valve opens and closes effectively, without turbulence, cavitation, or flow restrictions that could impair performance. Incorporating fluid dynamics enables engineers to optimize valve geometry for safe, consistent relief across various industrial applications.

How to Select the Right Custom Safety Valve for Your Industry Application?

Choosing the right custom safety valve involves aligning the valve’s specifications with the system’s exact needs:

- Media Type: Consider whether the valve will manage gas, liquid, or mixed-phase flows.

- Pressure & Temperature Range: Select a valve rated for expected operating extremes.

- Corrosiveness & Viscosity: These factors affect material and seal choices.

- Environmental Factors: Exposure to outdoor conditions or abrasive media influences design.

Beyond technical specs, industry standards and compliance play a role. For instance, oil and gas operations require different certifications than food or pharmaceutical environments. Partnering with an experienced manufacturer ensures the valve design meets both functional and regulatory demands.

What Are the Differences Between Pilot-Operated and Direct-Acting Safety Valves?

- Direct-Acting Valves use a spring mechanism to open once a preset pressure is exceeded. These are simple, fast-acting, and best for low to moderate pressure systems.

- Pilot-Operated Valves rely on a secondary pilot valve to control the main valve’s opening. They’re ideal for high-pressure, high-flow applications and offer better resealing capabilities and precision.

The choice between the two depends on system pressure, required response time, flow rate, and operational complexity.

How Do Industry Requirements Influence Custom Valve Design?

Each industry has unique operational and compliance demands that shape safety valve design. For example:

- Oil & Gas: Requires corrosion-resistant materials and valves rated for extreme pressures and temperatures.

- Pharmaceutical: Demands cleanability, sterility, and FDA-compliant materials.

- Power Generation: Often calls for high-capacity valves with precision control.

Industry-specific codes from ASME, API, NFPA, and ISO dictate design practices, material selection, and testing procedures. Custom valves must align with these standards to ensure safe and lawful operation in critical systems.

What Are the Benefits of Bespoke Safety Valve Designs?

Bespoke safety valve designs deliver tailored performance that generic valves cannot match. Benefits include:

- Precision Fit: Customized for the system’s exact flow and pressure characteristics.

- Improved Safety: Reduces the risk of overpressure and equipment failure.

- Reduced Maintenance: Optimized materials and seals improve longevity.

- Regulatory Compliance: Ensures valves meet required certifications from the start.

- Operational Efficiency: Lower risk of downtime due to improved performance and reliability.

Though upfront investment may be higher, the long-term returns in safety, efficiency, and cost savings make bespoke valves a strategic asset.

Which Safety Valve Compliance Standards Must Custom Designs Meet?

Custom safety valves must comply with several key standards:

- ASME BPVC Section VIII: Governs pressure relief devices for vessels.

- API 526 & 527: Focus on sizing, construction, and performance in petroleum applications.

- ISO 4126: Covers safety devices against excessive pressure.

- ANSI and NFPA Standards: Address installation, operation, and fire safety considerations.

Compliance with these standards ensures safe, reliable valve operation and helps businesses avoid fines or legal liabilities. Design engineers must integrate these requirements early in the custom development process.

What Are the Key ASME and API Standards for Safety Valves?

The most critical standards include:

- ASME Section I & VIII (BPVC): Regulates design, testing, and installation of valves used in boilers and pressure vessels. Compliance ensures valves can handle the required pressures without failure.

- API 526: Specifies dimensions and pressure-temperature ratings for spring-loaded pressure relief valves in refinery service.

- API 527: Defines seat tightness and testing procedures to verify leak-free performance.

Adhering to ASME and API standards guarantees reliability in mission-critical applications, such as refineries, chemical plants, and power stations. These standards are essential for system integrity and safety.

FAQs

How do PED and ATEX regulations affect safety valve manufacturing?

PED ensures that pressure equipment meets EU safety requirements, while ATEX governs valve suitability in explosive atmospheres. Compliance requires strict design documentation and quality controls.

Why are third-party certifications important for custom safety valves?

They verify that valves meet international safety standards and regulatory codes. Certifications like ASME, API, and ISO boost trust and facilitate global market acceptance.

What are the essential safety valve testing procedures for custom designs?

Critical procedures include hydrostatic testing, leak testing, set pressure verification, and functional testing under simulated conditions.

How is hydrostatic testing conducted on safety valves?

Valves are filled with water and pressurized beyond operating levels to ensure they do not leak or fail under pressure.

What performance tests ensure safety valve reliability?

Tests include blowdown accuracy, seat tightness, lift response, and back pressure handling to ensure operational reliability.

How can troubleshooting improve safety valve maintenance?

Identifying root causes of malfunctions—such as improper installation or material degradation—helps reduce downtime and extend valve life.

How does the custom safety valve design process work from concept to delivery?

It involves specification gathering, 3D modeling, material selection, prototyping, compliance checks, testing, and final manufacturing.

What are the steps involved in designing a custom safety valve?

Key steps: application analysis, engineering calculations, CAD modeling, material selection, prototyping, testing, and documentation.

How does ValveTech Solutions ensure quality and compliance during manufacturing?

They use certified materials, advanced testing, detailed traceability records, and quality management systems to ensure all standards are met.

What case studies demonstrate successful custom safety valve solutions?

Examples include solutions for LNG terminals, pharmaceutical cleanrooms, and offshore platforms—each showcasing reduced failure rates and regulatory compliance.

What industry trends and innovations are shaping custom safety valve designs?

Trends include digital monitoring, advanced alloys, AI-assisted diagnostics, and sustainable manufacturing practices.

How are advanced materials improving safety valve performance?

Materials like Inconel and titanium offer higher temperature resistance, corrosion protection, and lower maintenance.

What is the impact of digital technologies on safety valve monitoring?

IoT sensors enable real-time pressure tracking, predictive maintenance alerts, and remote diagnostics for proactive safety management.

How is sustainability influencing custom safety valve manufacturing?

Eco-friendly materials, energy-efficient processes, and recyclable components are reducing the environmental footprint of valve production.

How can you get expert consulting and support for custom safety valve solutions?

Many manufacturers offer engineering consultations, fluid dynamics analysis, and specification development support.

What consulting services are available for valve selection and maintenance?

Services often include on-site system assessments, valve audits, replacement planning, and training programs.

How can interactive tools help in custom safety valve selection?

Online configurators and flow simulators help users specify pressure, media, temperature, and other variables for faster, more accurate valve selection.

How to request a custom safety valve quote or consultation?

Visit the manufacturer’s website or contact their engineering team with system specs, compliance needs, and application details for a tailored quote.