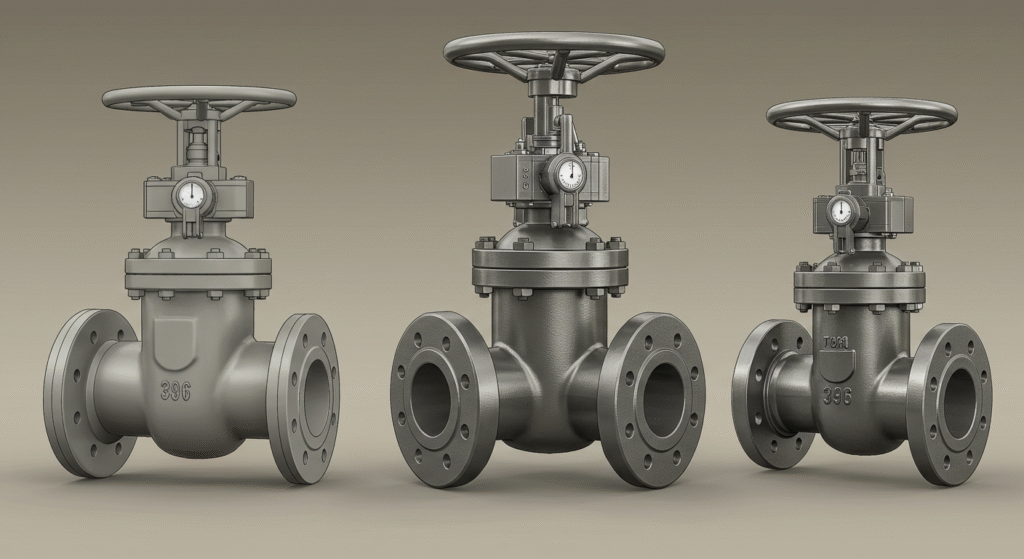

Safety valves are critical components in industrial safety systems that protect equipment and personnel from hazardous overpressure conditions. They are essential in industries such as oil and gas, chemical processing, and power generation, where they regulate pressure and prevent catastrophic failures that could lead to severe economic and environmental damage. Arpco Valves & Controls recognizes the need for robust, reliable valves engineered to meet stringent safety standards under extreme conditions. This article provides a technical guide on the core design principles, customization methods, key design steps, material selections, and performance advantages of safety valve design.

Transitioning to our first topic, we discuss the core design principles that underpin effective safety valve systems.

What Are the Core Safety Valve Design Principles in Industrial Engineering?

At the foundation of safety valve design are reliable pressure relief, precise control, and robust performance under varied conditions. Key considerations include pressure dynamics, material compatibility, operating temperatures, and strict adherence to safety standards. These factors guide engineers in designing valves that automatically release excess pressure, thereby preventing equipment failure and protecting personnel.

How Do Pressure Relief and Safety Relief Valves Differ?

Pressure relief valves and safety relief valves serve similar functions but operate differently. Pressure relief valves maintain system integrity during normal operations by gradually releasing excess pressure, while safety relief valves respond rapidly during emergency overpressure events. Their differences lie in response speed, capacity, and trigger mechanisms. Standards like the ASME Boiler and Pressure Vessel Code ensure these valves are calibrated to open at predetermined pressures, integrating redundant features to minimize the risk of failure.

Which Industry Standards Govern Safety Valve Design?

The design, manufacture, and testing of safety valves are governed by several key standards. The ASME Boiler and Pressure Vessel Code provides comprehensive guidelines to ensure valves can withstand operational stresses. Additionally, international standards such as ISO 4126 and regional regulations like Europe’s Pressure Equipment Directive (PED) enforce rigorous certification requirements. Compliance with these standards ensures the valves are safe, efficient, and globally recognized.

What Role Does Material Selection Play in Valve Reliability?

Material selection is vital to safety valve reliability. The choice of materials—carbon steel, stainless steel, or specialized alloys—directly affects durability, corrosion resistance, and thermal stability. For example, carbon steel offers strength in petrochemical environments, while stainless steel is preferred where corrosion resistance is critical. In extreme or corrosive conditions, specially engineered alloys and advanced coatings enhance the valve’s lifespan and overall performance.

How Does Fluid Dynamics Influence Valve Performance?

Fluid dynamics are central to valve design, determining the flow characteristics and pressure modulation capabilities. Engineers use computational fluid dynamics (CFD) simulations to optimize valve geometry, reduce turbulence, and minimize pressure drop. Such simulations influence key parameters like discharge coefficient, flow capacity, and response time, ensuring that valves perform efficiently in conditions such as steam systems or compressed natural gas pipelines.

How Are Safety Valves Customized for Specific Industrial Applications?

Customization involves tailoring the valve’s size, capacity, and trigger settings to meet unique process demands. Industrial settings—from oil refineries to chemical processing plants—require a careful assessment of operating conditions, hazards, and performance requirements. This iterative design process considers pressure parameters as well as chemical compatibility, temperature profiles, and flow characteristics.

What Factors Determine Valve Sizing and Set Pressure?

Determining the appropriate valve size and set pressure depends on the system’s operating pressure, maximum allowable working pressure, and the nature of the process fluid. Empirical formulas derived from industry standards help engineers calculate the necessary flow area and discharge capacity. In high-pressure applications like steam boilers, set pressure is typically positioned slightly above the normal working pressure to account for transient load changes and avoid over-relief in minor surges.

How Are Operating Conditions Assessed for Valve Selection?

Selecting the right safety valve requires a systematic evaluation of process conditions such as fluid temperature, pressure fluctuations, chemical composition, and environmental factors. Data from system sensors and historical logs help engineers analyze pressure transients and steady-state conditions. This detailed assessment ensures that the valve provides effective preventive protection and maintains performance during emergency conditions.

What Are the Benefits of Pilot-Operated Safety Relief Valves?

Pilot-operated safety relief valves use a secondary valve to control the main valve, achieving more precise pressure regulation. Their design enables smoother, quicker responses to overpressure conditions while reducing energy consumption. Adjustable pilot mechanisms improve stability and reliability, and their compact design makes them especially suitable for space-constrained applications like offshore platforms and mobile units.

What Are the Key Steps in Designing a Reliable Industrial Safety Valve?

Designing a reliable safety valve involves a structured process that includes risk analysis, prototyping, testing, and long-term validation. This methodology ensures that the valve performs as intended under all anticipated conditions.

How Is Risk Analysis Integrated Into Valve Design?

Risk analysis is essential for identifying potential failure modes such as overpressure, material fatigue, and thermal stress. Techniques like Failure Mode and Effects Analysis (FMEA) allow engineers to evaluate risks systematically, establish safety margins, and select robust materials. This approach not only enhances valve reliability but also serves as documented evidence for safety compliance during regulatory inspections.

What Testing and Validation Methods Ensure Valve Performance?

Extensive testing—such as hydrostatic, fatigue, and flow tests—is conducted to validate valve performance. Both destructive and non-destructive methods are used to measure opening pressure, response time, leakage rates, and structural integrity. Testing is performed in simulated environments that mimic real-world conditions, with periodic checks throughout the valve’s service life ensuring ongoing safety and functionality.

How Does Valve Maintenance Impact Long-Term Safety?

Long-term safety of a valve hinges on regular maintenance, which includes cleaning, recalibration, and component replacement. Continuous exposure to high pressures and corrosive environments necessitates proactive maintenance strategies, such as scheduled inspections and real-time monitoring. A well-documented maintenance routine ensures that valves remain functional and compliant with safety regulations, thereby preventing catastrophic failures.

Which Materials and Manufacturing Processes Enhance Safety Valve Durability?

The durability and longevity of safety valves are largely determined by the materials used and the manufacturing processes applied. Materials must endure high pressures, temperatures, and corrosive environments while resisting erosion and fatigue.

What Are the Most Common Materials Used in Industrial Safety Valves?

Common materials for safety valves include carbon steel, stainless steel, and high-performance alloys. Carbon steel is valued for its strength and cost-effectiveness in less corrosive settings, whereas stainless steel is ideal for environments with high humidity and chemical exposure. In severe conditions, materials like Inconel or Hastelloy, sometimes combined with advanced coatings, are selected to ensure prolonged durability.

How Do Manufacturing Techniques Affect Valve Quality?

High-quality manufacturing techniques such as precision forging, CNC machining, and laser cutting are critical to meeting tight tolerances and ensuring reliable performance. These processes minimize variability between units and guarantee that each valve adheres to strict design specifications. Advanced quality control measures, including non-destructive testing and computerized inspections, further enhance product consistency and performance.

What Corrosion Protection Methods Are Applied?

To combat corrosion, various protective methods are used, including surface treatments, polymer coatings, galvanizing, and electroplating. Advanced techniques like thermal spraying and powder coating ensure uniform protection and adhesion, which are especially important in aggressive chemical environments or coastal areas where salt and humidity accelerate corrosion.

How Do Safety Valves Protect Industrial Equipment and Personnel?

Safety valves are crucial for preventing overpressure scenarios that could lead to equipment failure, explosions, and other catastrophic events. By automatically discharging excess pressure, these valves safeguard both expensive industrial systems and the lives of personnel working in hazardous conditions.

What Are Typical Overpressure Scenarios in Industrial Settings?

Overpressure scenarios can occur due to sudden surges triggered by process upsets, equipment malfunctions, or thermal expansion events. For example, a rapid increase in temperature or flow rate in a boiler or storage tank can push pressures beyond design limits. By opening automatically before structural failure occurs, safety valves prevent rupture and explosions, thereby reducing downtime and injury risks.

How Do Safety Valves Prevent Equipment Failure?

Safety valves protect equipment by venting excess pressure, which alleviates mechanical stress and prevents fatigue, rupture, and catastrophic explosions. Maintaining pressure within safe limits protects pressure vessels, pipelines, and tanks and extends the operational life of industrial systems. The preset activation thresholds are critical for ensuring timely operation during both normal and emergency conditions.

What Are the Safety Benefits for Personnel and Environment?

Beyond protecting equipment, safety valves reduce the risk of explosions and hazardous chemical releases. By controlling overpressure, they mitigate situations that could lead to fires, toxic leaks, and other environmental hazards. This controlled pressure relief supports overall process safety and helps create a safer workplace for personnel while protecting the surrounding environment.

What Are Common Challenges and Solutions in Safety Valve Design?

Designing safety valves involves overcoming challenges such as harsh operating conditions and evolving regulatory demands. Issues like material degradation, inconsistent performance, and the need for compliance with rigorous standards require innovative solutions.

How Is Valve Performance Affected by Harsh Operating Conditions?

Extreme temperatures, corrosive fluids, and fluctuating pressures can lead to deformation, erosion, and fatigue of valve components. In environments like petrochemical plants or high-temperature steam systems, robust material selection, effective coatings, and careful design margins are essential to maintain performance. Regular maintenance and precise engineering help counter these harsh conditions.

What Design Innovations Improve Valve Reliability?

Recent innovations such as smart sensors, advanced CFD modeling, and modular designs have greatly enhanced valve reliability. Pilot-operated mechanisms paired with electronic monitoring allow for real-time performance diagnostics and remote adjustments. These improvements not only provide faster response times and precise pressure control but also help reduce maintenance costs and unplanned downtime.

How Are Compliance and Customization Balanced in Design?

One of the biggest challenges is balancing strict regulatory compliance with the need for customized solutions tailored to specific industrial applications. Manufacturers address this by employing modular designs that allow adjustments in sizing, material, and pressure settings while still meeting standards like those set by ASME and ISO. This balanced approach ensures that customized valves are both safe and optimized for their intended applications.

How Can Industrial Companies Ensure Compliance and Optimal Valve Performance?

Ensuring optimal valve performance and regulatory compliance involves proper installation, regular maintenance, and a commitment to quality assurance. Industrial companies must partner with experienced manufacturers and service providers to incorporate best practices throughout the valve’s lifecycle.

What Are Best Practices for Valve Installation and Commissioning?

Correct installation is vital. Valves must be installed by trained professionals following manufacturer guidelines to ensure proper alignment, calibration, and documentation. Comprehensive commissioning tests verify that the valve meets the set pressure and flow specifications. Regular audits and commissioning reports further help maintain operational safety.

How Should Safety Valves Be Maintained and Inspected?

A regimen of scheduled maintenance and systematic inspections is crucial for early detection of wear and potential failures. Periodic recalibration, cleaning, and pressure testing—supported by real-time monitoring systems—ensure that valves perform reliably over time. Such practices not only prolong the service life of valves but also support compliance with industry standards.

What Support Services Enhance Valve Lifecycle Management?

Enhanced lifecycle management is achieved through support services like remote monitoring, predictive maintenance, and comprehensive after-sales support. These services provide real-time data, anticipate potential issues, and offer expert guidance, thereby maximizing uptime and ensuring consistent valve performance. Additionally, tailored maintenance contracts and operator training further reinforce long-term reliability.

Detailed Comparison Table of Safety Valve Design Attributes

Before the FAQs, consider the summary table below comparing key attributes of safety valves based on material, design innovation, and operational benefits.

Material/Attribute | Common Materials | Key Innovations | Operational Benefit | Industry Standard Compliance |

Structural Integrity | Carbon Steel, Alloy | Precision Forging, CNC | High mechanical strength and endurance | ASME Boiler and Pressure Vessel Code |

Corrosion Resistance | Stainless Steel | Advanced Coatings | Reduced wear and extended lifespan | ISO 4126, Pressure Equipment Directive |

Pressure Regulation | High-Performance Alloys | Pilot-Operated Mechanism | Accurate pressure relief and rapid response | ISO and regional regulatory frameworks |

Thermal Stability | Inconel, Hastelloy | CFD Simulation | Reliable performance in high temperatures | Certification as per industry safety guidelines |

Customization Flexibility | Modular Design | Remote Monitoring, Predictive Maintenance | Tailored solution for diverse applications | Global safety certifications |

This table encapsulates the essential aspects of safety valve design, highlighting how proper material selection, innovative manufacturing, and advanced support services drive optimal performance and regulatory compliance.

Frequently Asked Questions

Q: What is the primary function of a safety valve in industrial systems?

A: A safety valve automatically releases excess pressure from systems such as boilers, pressure vessels, and pipelines to prevent overpressure, equipment damage, and catastrophic failures. It helps maintain system stability while protecting both machinery and human life.

Q: How do industry standards influence safety valve design?

A: Industry standards—such as those from ASME, ISO 4126, and the Pressure Equipment Directive—set rigorous benchmarks for material selection, design parameters, testing protocols, and certification. Adhering to these standards ensures safety valves are reliable and accepted globally.

Q: What role does computational fluid dynamics (CFD) play in valve design?

A: CFD enables engineers to simulate fluid flow through a valve, optimizing its geometry to reduce turbulence and pressure drop while improving flow capacity and response time. This results in valves that perform efficiently under real-world conditions.

Q: Why is preventive maintenance essential for safety valves?

A: Regular maintenance—including inspections, recalibrations, and component replacements—ensures that safety valves function properly over time. Preventive practices help detect early signs of wear and corrosion, ensuring compliance and minimizing unexpected downtime.

Q: How can companies customize safety valves to suit specific applications?

A: Companies tailor valve parameters such as sizing, set pressure, material composition, and coatings based on detailed assessments of operating conditions like temperature, pressure fluctuations, and chemical exposure. Customized designs may also integrate remote monitoring to ensure optimal performance.

Q: What challenges are typically encountered during safety valve design?

A: Common challenges include managing harsh conditions such as high temperatures, corrosive fluids, and rapid pressure changes. Engineers must balance strict regulatory compliance with the need for performance enhancements, using advanced materials, precise manufacturing, and rigorous testing to overcome these issues.

Q: What support services are available to enhance the lifespan of safety valves?

A: Support services such as remote monitoring, predictive maintenance, and technical assistance provide real-time performance insights and early fault detection. These services, along with maintenance contracts and operator training, help ensure the valves remain in optimal condition throughout their lifecycle.