Safety valves are critical in industrial settings, especially in the oil and gas industry. They ensure that machinery, pressure vessels, and piping systems operate safely by preventing overpressurization that can lead to catastrophic failures. This article provides an in‐depth analysis of the standards and criteria governing safety valve design. It covers ASME, API, and EN standards; explains overpressure protection principles; outlines compliance requirements; and offers guidance on selecting, maintaining, and inspecting safety valves. Recent trends and updates in safety valve design are also discussed, enabling plant managers, engineers, and safety professionals to enhance equipment reliability and protect personnel and assets.

What Are the Key Safety Valve Design Standards?

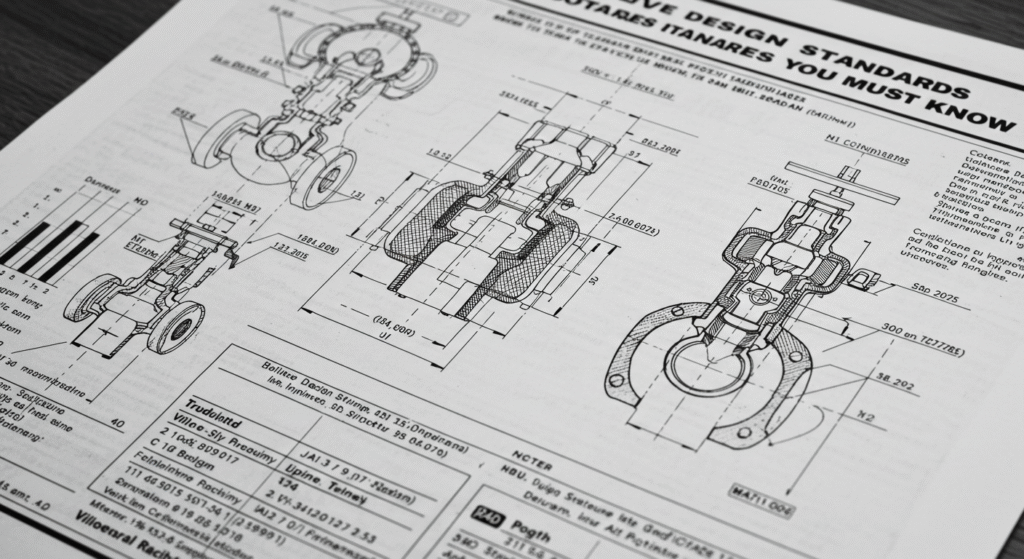

Safety valve design standards define the critical attributes of safety valves including materials, dimensions, performance, and installation practices. International organizations such as ASME, API, and EN publish codes and guidelines that manufacturers and end-users must follow. These standards require valves to withstand rigorous tests for pressure limits, cyclic fatigue, and over-temperature resistance while minimizing corrosion and wear. Detailed provisions on material selection, design tolerances, and performance testing ensure the valve meets strict safety and reliability criteria.

Which ASME Standards Apply to Safety Valve Design?

ASME standards are the backbone for designing pressure-containing equipment. Codes like the ASME Boiler and Pressure Vessel Code (BPVC) Section I and Section VIII set forth design, fabrication, and inspection requirements for valves in high-pressure environments. They specify minimum design requirements – such as valve size, set pressure, and safety margin – and mandate testing under simulated operational pressures. Adherence to these standards means a valve installed on a boiler system undergoes rigorous evaluation through documented design calculations, test results, and material certifications, thus ensuring regulatory compliance and helping plant managers plan maintenance and upgrades.

How Do API Standards Influence Safety Valve Requirements?

The American Petroleum Institute (API) develops standards focused on the oil and gas sector. API standards like API 520 and API 526 provide guidelines for selecting, installing, and maintaining safety valves. They emphasize valve sizing and pressure-temperature ratings tailored to the unique challenges of petroleum processing. In refinery operations, for example, safety valves must control pressure and minimize ignition risks. API guidelines include risk assessments, performance criteria, regular testing schedules, and strict record-keeping, ensuring that valves consistently meet the rigorous demands of the industry.

What Are the EN Standards for Safety Valves?

European Norms (EN), established by the European Committee for Standardization (CEN), are widely applied across Europe. EN standards such as EN 764 and EN 13445 address manufacturing and performance criteria, with added requirements for environmental sustainability and compatibility with European regulations. These standards focus on design integrity, durability, and material quality. They incorporate guidelines for corrosion resistance, operating temperatures, and pressure ratings to prevent valve failure while requiring robust documentation and third-party certification for maintenance and inspections.

How Do Safety Valve Design Standards Ensure Overpressure Protection?

Overpressure protection is fundamental to process safety, safeguarding equipment and personnel by venting excess pressure. Safety valve design standards dictate stringent performance criteria and testing regimes based on careful analysis of system behavior and failure modes. They require valves to automatically vent pressure when it exceeds predetermined limits, thus reducing risks of explosions, pipe ruptures, or structural damage.

What Is Overpressure Protection and Why Is It Critical?

Overpressure protection is the implementation of mechanisms to relieve excess pressure before damaging levels are reached. In high-pressure environments, even a small malfunction can lead to rapid pressure build-up, risking severe infrastructure damage and loss of life. By mandating that valves open automatically at specific thresholds, design standards dissipate excess energy, maintain system integrity, and have been shown to reduce risk substantially.

How Do Design Standards Address Pressure Relief Valve (PRV) Performance?

PRV performance is essential for safety valve design. Standards require that PRVs react rapidly to pressure fluctuations and temperature changes by specifying minimum discharge capacity, response time, and durability. Manufacturers validate these requirements through testing such as endurance trials and simulated operational scenarios. Testing methods include computational modeling (like CFD) and cyclic loading tests to ensure that PRVs not only meet but often exceed performance benchmarks.

What Testing and Certification Are Required for Compliance?

To certify a safety valve, it must undergo hydrostatic tests, cyclic fatigue tests, and functional performance tests in simulated environments. Certification agencies, guided by ASME, API, and EN, provide third-party validation of these tests. The process involves detailed inspections of manufacturing processes, material properties, and assembly procedures, with extensive documentation maintained throughout a valve’s lifecycle. Regular audits and re-certifications ensure continuous compliance, reinforcing public trust and operational safety.

What Are the Essential Compliance Requirements for Safety Valve Design?

Compliance requirements span technical and regulatory factors including design specifications, material selection, dimensional tolerances, and testing protocols. These requirements are enforced through comprehensive documentation and adherence to recognized standards, ensuring safe operation and reducing liability risks.

How to Achieve Compliance With Industry Safety Regulations?

Compliance is achieved by selecting certification-compliant products and maintaining meticulous documentation and regular maintenance audits. Manufacturers design safety valves with rigorous performance criteria and then subject them to thorough testing and third-party certification. A robust quality control system—with routine inspections, detailed logbooks, and digital records—is essential. Integration of advanced sensor technology further enables real-time performance tracking to proactively address deviations and maintain compliance.

What Documentation Is Needed for Safety Valve Certification?

Certification documentation must include detailed engineering drawings, material certificates, manufacturing processes, and calibration test results. Records of weld certifications, stress tests, and conformance with pressure vessel codes offer vital references during maintenance and audits. Maintaining complete production records and quality assurance data is crucial for continuous improvement and regulatory inspections.

How Do Plant Managers and Safety Professionals Ensure Compliance?

Plant managers and safety professionals ensure compliance through a proactive approach involving regular inspections, functional tests, and strict documentation practices. They use comprehensive checklists based on ASME, API, and EN standards to verify that each valve meets current regulatory requirements. Digital maintenance systems that monitor pressure, temperature, and operation parameters help detect anomalies early, while regular training and certification updates ensure staff remains informed of the latest standards.

How to Select the Right Safety Valve According to Design Standards?

Selecting the right safety valve ensures effective management of pressure-related incidents under varying operating conditions. The process involves evaluating system pressure, fluid characteristics, material compatibility, and environmental conditions, ensuring compliance with regulatory standards while optimizing performance.

What Factors Influence Safety Valve Selection?

Key factors include the maximum allowable working pressure (MAWP), discharge capacity, and temperature range. The properties of the working fluid—viscosity, corrosiveness, and phase—are also critical. Material selection plays a crucial role; for example, valves used in corrosive environments should be made of carbon steel, cast iron, or specialized alloys. Additionally, the intended application—whether for compressors, pumps, or turbines—determines the valve’s design, mounting, and actuation mechanism. In an oil refinery, a valve on a high-pressure compressor must handle high discharge and resist corrosion. Computational models and CFD simulations are often used to verify performance before final selection.

How Do Engineering Design Services Support Valve Selection?

Engineering design services aid in integrating safety valves into complex systems by evaluating technical specifications, performing risk assessments, and using simulation tools to predict valve behavior. They help reconcile conflicting design requirements, such as maximizing flow capacity while minimizing pressure drop, and often collaborate with manufacturers to customize valve designs that meet specific operational needs.

What Are Common Mistakes to Avoid in Safety Valve Selection?

Common mistakes include relying solely on discharge capacity without considering fluid dynamics, temperature, or material compatibility, and neglecting the effects of cyclic loading. Using outdated specifications or ignoring regulatory updates can also lead to costly downtime. A comprehensive evaluation with simulation and expert consultation is essential to avoid these pitfalls and ensure a compliant and reliable valve selection.

How to Maintain and Inspect Safety Valves to Meet Design Standards?

Regular maintenance and inspection of safety valves are as important as design and selection. Scheduled testing, cleaning, recalibration, and replacement of worn parts not only extend valve life but also prevent unexpected failures that could disrupt operations.

What Are the Recommended Maintenance Practices?

Key maintenance practices include scheduled inspections, functional testing, and cleaning. Periodic recalibration of valve set pressures ensures proper relief during design-specified conditions. Visual inspections and non-destructive tests, such as ultrasonic or radiographic methods, help detect material fatigue or corrosion early. Maintaining detailed service records for each valve supports traceability and accountability, while preventive maintenance routines—whether monthly or quarterly—ensure timely detection and correction of any issues.

How Often Should Safety Valves Be Inspected and Tested?

Inspections and testing frequencies depend on regulatory standards and operating conditions. Typically, valves are inspected and tested annually; however, in high-cycle or corrosive environments, semi-annual or quarterly testing may be necessary. Interim “pop tests” can verify responsiveness during overpressure conditions. Real-time monitoring and periodic third-party inspections further support continuous compliance.

What Are the Signs of Non-Compliance in Safety Valve Performance?

Signs of non-compliance include visible wear, corrosion, leaking, delayed actuation, variations in discharge capacity, and deviations in set pressure. Regular diagnostic tests with pressure gauges and electronic sensors are essential to detect anomalies early. Any inconsistency with specified performance criteria requires immediate corrective action to avoid downtime or hazardous conditions.

What Are the Latest Updates and Trends in Safety Valve Design Standards?

Safety valve design is continuously evolving, driven by advancements in materials science, digital monitoring, and environmental regulations. Recent updates reflect a shift towards robust, automated, and eco-friendly solutions that remain compatible with modern industrial processes and complex control systems.

How Are Safety Valve Standards Evolving Globally?

Globally, standards are being revised to incorporate emerging technologies and new materials. ASME, API, and EN are updating guidelines to address challenges such as enhanced corrosion resistance and better integration with digital monitoring systems. New standards now specify requirements for smart safety valves that include real-time diagnostics and remote monitoring, enabling proactive maintenance and improved safety.

What Innovations Are Influencing Safety Valve Design?

Innovations such as advanced composite materials, additive manufacturing (3D printing), and smart sensors are significantly impacting safety valve design. Composite materials reduce corrosion while extending valve life, and additive manufacturing allows for complex geometries and tighter tolerances. Integration of smart sensors enhances predictive maintenance by monitoring performance in real time, reducing design errors and overall testing costs.

How Can Companies Stay Updated on Compliance Changes?

Companies can stay current by engaging in industry publications, attending standard-setting conferences, and collaborating with regulatory bodies. Subscribing to technical newsletters and participating in trade shows helps firms track design, testing, and certification updates. Additionally, implementing compliance management systems and forming internal task forces ensure that any changes in standards are promptly addressed through updated procedures and training sessions.

Why Is Understanding Safety Valve Design Standards Critical for Industrial Process Safety?

Understanding these standards is crucial for ensuring that industrial processes operate safely and efficiently. Safety valves protect equipment from overpressure, avoid regulatory non-compliance, and mitigate potential operational hazards. When properly integrated, they serve as a first line of defense against catastrophic failures, significantly lowering risks to both personnel and assets.

How Do Safety Valves Protect Industrial Equipment and Personnel?

Safety valves automatically relieve excess pressure from boilers, pressure vessels, compressors, and pipelines, preventing structural damage and failure. Their design, based on rigorous standards, ensures precise actuation at designated pressure thresholds, which not only preserves equipment integrity but also minimizes injury risks. Regular testing and maintenance further enhance their reliability in protecting both human and financial capital.

What Are the Consequences of Ignoring Design Standards?

Failing to follow design standards can result in overpressure failures, equipment damage, and operational downtime. Non-compliance may also lead to hefty fines, legal issues, and reputational damage. Historical incident analyses show that errors in valve selection, maintenance neglect, or deviation from standards often cause preventable accidents, detailed in repair costs, lost production, and regulatory penalties.

How Can Safety Professionals Leverage Standards for Better Safety Outcomes?

Integrating design standards throughout the equipment lifecycle—from design to installation and maintenance—enables safety professionals to implement robust monitoring systems and continuous improvement practices. Regular inspections, maintenance tests, and data analysis help detect potential failures early. Digital tools like predictive analytics and smart sensors further enhance risk management, while comprehensive training and documentation ensure that every stakeholder understands and adheres to these critical standards.

Table: Comparison of Safety Valve Design Standards

Below is a summary table comparing key characteristics of ASME, API, and EN safety valve design standards.

Standard Body | Key Focus Areas | Critical Parameters | Testing & Certification | Industry Usage |

ASME | Boiler/Pressure Vessel Design | MAWP, flow capacity, material strength | Hydrostatic and cyclic testing | Worldwide, especially in North America |

API | Oil & Gas Industry Safety Valves | Pressure relief rate, discharge capacity, environmental hazards | In-field and simulated performance tests | Global, with emphasis on petrochemical applications |

EN | European Industrial Standards | Corrosion resistance, dimensional tolerances, eco-friendly materials | Third-party certification, periodic audits | Used across Europe and international exports |

Before deploying safety valves, companies should use this comparative data to select products that best suit their operational contexts. Integrating this table into the decision-making process supports informed investment in reliable and compliant safety solutions.

Frequently Asked Questions

Q: What role do safety valve design standards play in overpressure protection?

A: They establish the performance, material, and testing criteria to ensure valves reliably relieve excess pressure, preventing catastrophic failures through accurate actuation and rigorous certification.

Q: How often should safety valves be inspected to remain compliant?

A: Valves are typically inspected and tested annually, with more frequent (semi-annual or quarterly) testing in harsh environments. Regular maintenance and recalibration quickly identify early signs of wear or non-compliance.

Q: What are the most common factors that influence the selection of a safety valve?

A: Key factors include the maximum allowable working pressure, discharge capacity, material compatibility, fluid characteristics, operating temperature, and environmental conditions; consulting ASME, API, and EN standards ensures all parameters are addressed.

Q: How do engineering design services support the safety valve selection process?

A: They evaluate system parameters, perform risk assessments, and use simulation tools to verify performance requirements, ensuring the selected valve is both compliant and reliable in demanding conditions.

Q: What innovations are emerging in safety valve technology?

A: Innovations include advanced composite materials for improved corrosion resistance, additive manufacturing for complex designs, and smart sensor integration for real-time monitoring, all of which enhance sustainability and predictive maintenance.

Q: Can companies easily update their safety valve systems when standards change?

A: Yes, companies can update their systems by staying informed through industry publications, conferences, and training programs. Compliance management systems and regular audits ensure that any new standard changes are promptly implemented.

Q: How do safety valve standards contribute to reducing operational downtime?

A: By ensuring reliable operation during overpressure events, these standards minimize the risk of failures that can halt production. Proper documentation, routine maintenance, and timely inspections keep systems running smoothly and reduce unexpected downtime.